Enhancing ID Security: The Unrivaled Potential of Polycarbonate Material Introduction

SHANGHAI RIJER INDUSTRIAL CO.,LTD

In an era of increasing digital advancements, the importance of physical identification cards remains paramount. The demand for secure and durable identification (ID) cards has led to a notable surge in the utilization of polycarbonate material within the ID security card market. With its remarkable properties, polycarbonate has emerged as an unrivaled choice for ID card manufacturers worldwide. This article delves into the myriad benefits of using polycarbonate material, highlighting its superior security features, durability, and versatility.

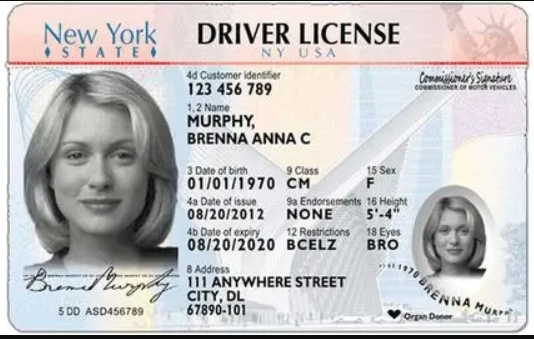

Polycarbonate film is a crucial component used in the production of ID cards and e-passports, Driver License etc

Unparalleled Security Features

Polycarbonate material has become synonymous with enhanced ID card security due to its exceptional resistance to forgery and tampering. The inherent nature of polycarbonate makes it incredibly difficult to counterfeit, providing robust protection against unauthorized replication. Its high resistance to scratching and abrasion ensures that crucial information remains intact and legible, bolstering security against malicious alteration attempts.

Moreover, polycarbonate ID cards can incorporate advanced security elements such as holograms, microtext, and laser engraving. These features, coupled with the material's transparency, allow for intricate designs and personalized visual effects that are difficult to replicate. The resulting ID cards are not only aesthetically appealing but also provide an added layer of security, enabling authorities to quickly and accurately verify authenticity.

Unrivaled Durability

One of the primary concerns with ID cards is their ability to withstand daily wear and tear. Polycarbonate material shines in this regard, offering unmatched durability and longevity. Its inherent toughness and resistance to impact make it highly suitable for applications where cards are subjected to frequent handling, such as identification badges, access control cards, and driver's licenses.

The robust nature of polycarbonate ensures that ID cards retain their structural integrity, even in adverse conditions. They are capable of withstanding extreme temperatures, moisture, and exposure to chemicals, making them ideal for outdoor and industrial environments. This durability factor significantly reduces replacement

costs, making polycarbonate ID cards a cost-effective long-term solution for organizations.

Versatility and Customizability

Polycarbonate material offers a vast array of customization options, empowering organizations to create unique and distinct ID cards that align with their branding requirements. The material's flexibility allows for intricate designs, color variations, and the integration of various security features. This versatility enables organizations to tailor their ID cards to specific applications, be it employee identification, student cards, or government-issued documents.

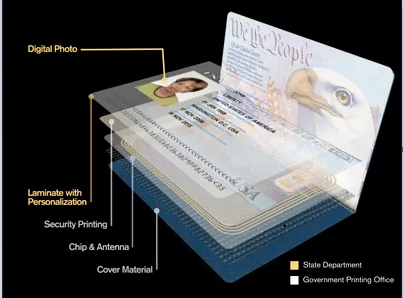

Additionally, polycarbonate cards can incorporate advanced technologies like contactless smart cards and RFID chips. These technologies facilitate secure access control and enable multifunctional applications, including cashless payments, public transportation passes, and digital authentication.

Sustainability Considerations

In recent years, environmental sustainability has become a pressing concern. Polycarbonate material offers a positive contribution to the environment due to its recyclability and energy efficiency during the production process. ID cards made from polycarbonate can be recycled, reducing the overall environmental impact compared to other less eco-friendly materials.

Furthermore, the durability and longevity of polycarbonate ID cards significantly reduce waste by extending their lifespan and minimizing the need for frequent replacements. This sustainable aspect not only benefits organizations but also aligns with global efforts towards a greener future

SHANGHAI RIJER INDUSTRIAL CO.,LTD Polycarbonate material Introduce:

Polycarbonate Core White(PC White Core) refers to the central layer of polycarbonate material used in the construction of ID security cards. It serves as the foundation that provides strength, durability, and security to the overall card structure.

Thickness range : 80micron ~800micron

Thickness used in large quantities:100micron,120micron,150micron 200micron,300micron

Size: Any Size

Polycarbonate Uncoated Laser Film(PC Laser Overlay Film):

Polycarbonate uncoated laser film refers to a specialized film made from polycarbonate material that is used for laser engraving purposes on ID security cards

1. Laser Engraving Compatibility: Polycarbonate uncoated laser film is specifically designed to be compatible with laser engraving technology. The film is engineered to withstand the intense heat and precision of laser engraving equipment, ensuring accurate and consistent results.

2. High Clarity and Transparency

3. Security Enhancements

4. Durability and Longevity

Thickness range : 40micron ~300micron

Thickness used in large quantities:50micron,75micron,100micron,120micron,150micron

Size: Any Size

Plastic cards, Smart cards, Bank cards, credit card, PETG card,PVC white core, PVC Laser overlay filM , Hololam foil, Recycled PVC Cards,ID Security cards, government, ID cards, passport , driver licenses,Smart cards inlays,HP indigo sheet, Inkjet material, digital cards,HOLOGRAPHIC FOIL,dual interface card, Magnetic Stripe Card,Polycarbonate card, Polycarbonate white core, Polycarbonate laser overlay,PETG white core, PLA cards .

Customer Manager

Customer Manager